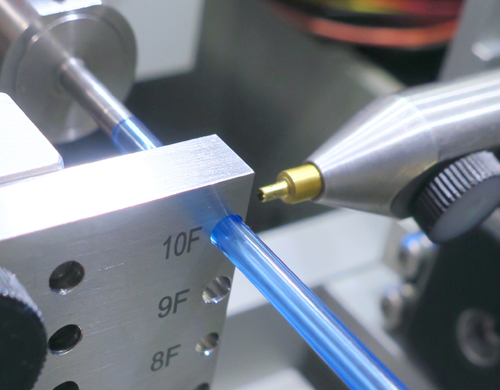

Customized Catheter Hole Punching Machines

Gain efficiency in your clean room with Cath-Punch’s customization & automation options:

robotics • auto-feeding • vision systems • dual drill heads • multi-part operation

tabletop automation • palletized part loading • multiple hole sizes in one machine cycle

Catheter hole punching video: 2 wall customization

Cath-Punch engineers assess your needs to design a custom system.

Cath-Punch equipment can be customized per your application, including our 400-Series semi-automated catheter hole punching machines.

Beyond the standard benefits of superior holes, speed, flexible controls, intuitive touchscreen HMI, light curtain safety circuits, various sensor capabilities, tool-free drill bit and fixture change-overs, etc. – we also offer custom machine development for advanced needs.

You receive bonus features to give you the desired production efficiencies you seek.

Quickly punch clean, burr-free holes. Cath-Punch’s proprietary hole drilling technology gives your production process speed and accuracy. Cores are evacuated at the moment of creation to keep your clean room workstations pristine.

Cath-Punch equipment is a staple of catheter hole drilling operations in the medical manufacturing industry.

Request samples to see the hole quality yourself!

Catheter Hole Punch Benefits:

• High Precision, Four Axis, Open Loop, Stepper Motor Controlled Motion

• Flow Thru™ Vacuum Equipped

• Core Capture Technology

• Designed for Tool-Free Drill Change & Interchangeable Tooling

• Auto Drill Detection & Homing

• HMI Controlled with Status Alerts & Process Inputs

• Integrated Drill Cycle / Parts Count

• Small Footprint Tabletop Workstation (approx. 18”W x 33”L)

• Full Safety Shields -or- Light Curtains

• Integrated Emergency Stop

View our 400-Series semi-automated catheter hole punching machines.

View our smaller, lower-cost, MI-Series pneumatic machine with manual indexing.