Catheter Hole Drilling with Flow Thru™ Hollow Drills

Attain the highest quality hole appearance and reduce manufacturing costs. Enjoy fast throughput and infrequent drill bit changes.

Benefit from CATHTIP’s proprietary Flow Thru™ hollow design drills in your high volume production environment. The ground edge and the exact geometry of the drills make holes that are rounded on the outside and burr free on the inside.

Flow Thru™ Hollow Drills

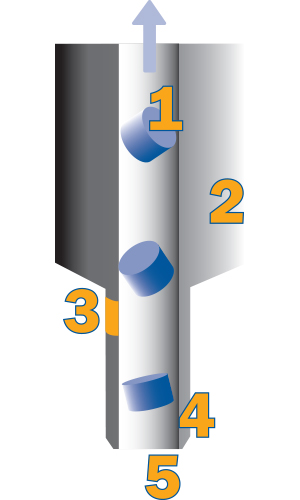

(graphic close-up representation of drill bit and cores)

1. Cores flow through drill bit to be captured in filter chamber

(work area is kept free of hole cores)

2. Hardened steel with titanium nitride coating

(long life cutting through polymers containing abrasive BaSO4, TiO2, and Silica)

3. Down to .0015″ wall thickness

(minimal plastic cold flow around holes)

4. Stiff cutting tip and high concentricity

(no scuff marks at hole entry and no bending or vibration during drilling)

5. Extremely sharp cutting edge

(clean cut at hole exit)

The catheter hole cores travel from the drill bits and continue their isolation as they flow directly into a collection chamber.

Ground Edge

The fine sharpness of the drills is achieved by grinding with very fine grit wheels. This allows the drill to cut cleanly with minimal resistance. Our attention to detail serves your catheter hole drilling production needs and gives you a better product. Ask us about drill resharpening services.

Use of hardened 440C wear resistant stainless steel with a TiN coating make for high strength with long wear life.

Need to order more drills or request resharpening? Have catheter hole drilling questions?

435-628-1775 [email protected]

View catheter hole drilling in action!

Go to more information on automatic catheter hole drilling machines.

Go to more information on Flex Drill catheter hole drilling device.