NG-Series Machine

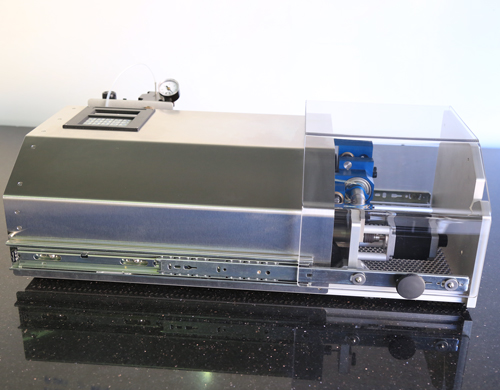

Save time and money when catheter hole drilling with Cath-Punch’s automated catheter hole punch machine. Make clean and fast holes with this table top, four axis stepper motor controlled machine.

Proprietary hole drilling technology gives your production process a boost of speed and accuracy. Quickly punch clean, burr-free holes with our automated catheter hole punch equipment.

Tell us about your project. We develop the process and show you samples for approval. You receive custom machines to suit your catheter manufacturing needs.

Your customers demand quality and our machines deliver. Our continuous advancements have made Cath-Punch equipment a staple of catheter hole drilling operations and tops in the medical manufacturing industry.

Catheter Hole Punch Benefits:

Speed • Quality • Captured Cores • Hole Verification • Flexibility • Versatile Tooling • Low Operating Cost • Quick and Easy Set-up

Speed

Five holes can be made in a second

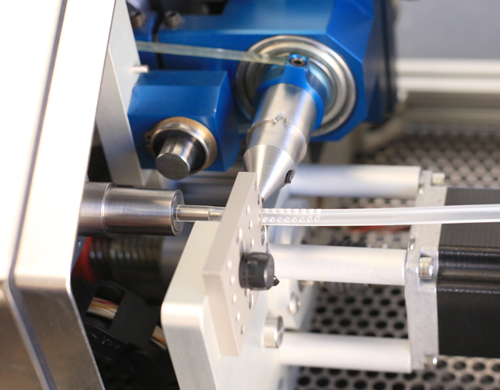

4 axis stepper motor control. Stepper motors, 50,800 steps/rev, matched to the inertia of the driven mechanism makes for steep and controlled acceleration ramps in four axis (drill feed, drill rotation, linear index, rotary index). Multiple catheter hole punch drill heads can be added to increase cutting speed.

Quality

Clean, controlled holes

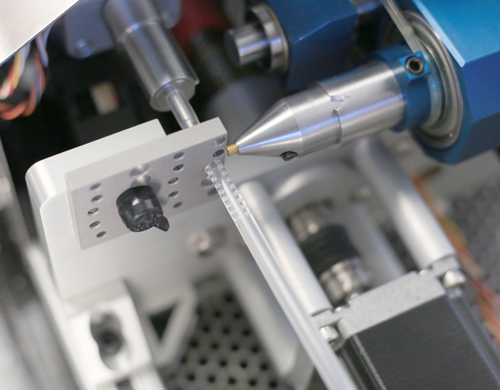

Cutting parameters stored in the program of the machine drive the drill precisely through the wall of the catheter to make a hole that is rounded on the outside and burr free on the inside. Both drills and catheter are held in position with high accuracy to deliver the utmost results.

Captured Cores

No loose cores

The cores are immediately evacuated through the drill bit at the moment of creation – therefore isolating them completely as they then travel through the machine and are captured in a filter chamber. This virtually eliminates the chance of loose cores in the catheter or uncut holes, while keeping the work area clear of debris.

Hole Verification

Safety Assurance

To assure cores aren’t remaining in drilling holes we offer an option to verify catheter holes are clear of cores and other debris. This option will catch a poorly set up machine and a dulling drill bit.

Flexibility

Wide range of applications

The machine can accept catheter diameters from 3 French (0.040˝) to 28 French (0.368˝). Hole diameter down to 0.018˝. The linear indexer can be stretched to accommodate hole spacing to 4 feet. The machine can be adapted with multiple drill heads to make two or three different hole diameters in one drill cycle.

Versatile Tooling

Suitable for many lumen configurations

The machine can be tooled for complex lumen configurations. This includes double Dee, concentric tubes, double barrel shotgun, crescent moon, 8 lumen etc. High magnification camera can be added to accurately locate the smallest lumen.

Low Operating Cost

No disposable mandrel

The cost of a disposable inner mandrel is eliminated in our catheter hole punch. The sharp cutting edge of the drill can eliminate the need for an inner support. When the sharp edge is inadequate for difficult materials we use a permanently mounted soft tip mandrel to replace the disposable inner mandrel.

Quick and Easy Set-Up

Fast because parameters stored in memory

All set-up parameters are stored in the memory of the stepper motor controller. As many as seven different set-ups can be stored. The person changing a set up only needs to change the drill bit, zero the drill bit edge against the surface of the catheter, and move a tooling plate to a new position. An experienced technician can do this in a couple of minutes.

Key benefits and features of the NG-Series automated catheter hole punch machines:

(view or download pdf)

Cath-Punch NG-Series Technical Details:

Needing a smaller, lower-cost, pneumatic machine with manual indexing? Cath-Punch’s MI-Series equipment might be what you need.